Ropetec – das sind wir

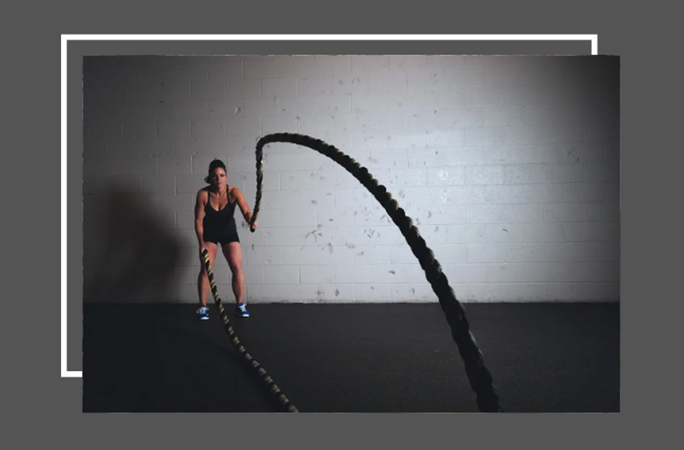

Ropetec ist ein Spezialbetrieb für die Verarbeitung von Tauwerken und Herstellung von Seilerwaren. Unsere jahrzehntelange Erfahrung im Spleißerhandwerk macht uns zum führenden Spezialisten auf dem Gebiet. Individuelle Anfertigungen für Einzellösungen sind unser Fachgebiet, aber auch die Massenherstellung von konfektionierten Produkten ist das täglich Brot von Ropetec.

Uns ist kein Auftrag zu klein und keine Herausforderung zu groß. Das Leben mit den Kunden liegt uns am Herzen. Wir nehmen daher jede Anfrage ernst und bemühen uns, unseren Vorteil der hersteller- und konstruktionsunabhängigen Verarbeitung für Sie auszuspielen.

Lassen Sie sich von unseren Fähigkeiten überzeugen!